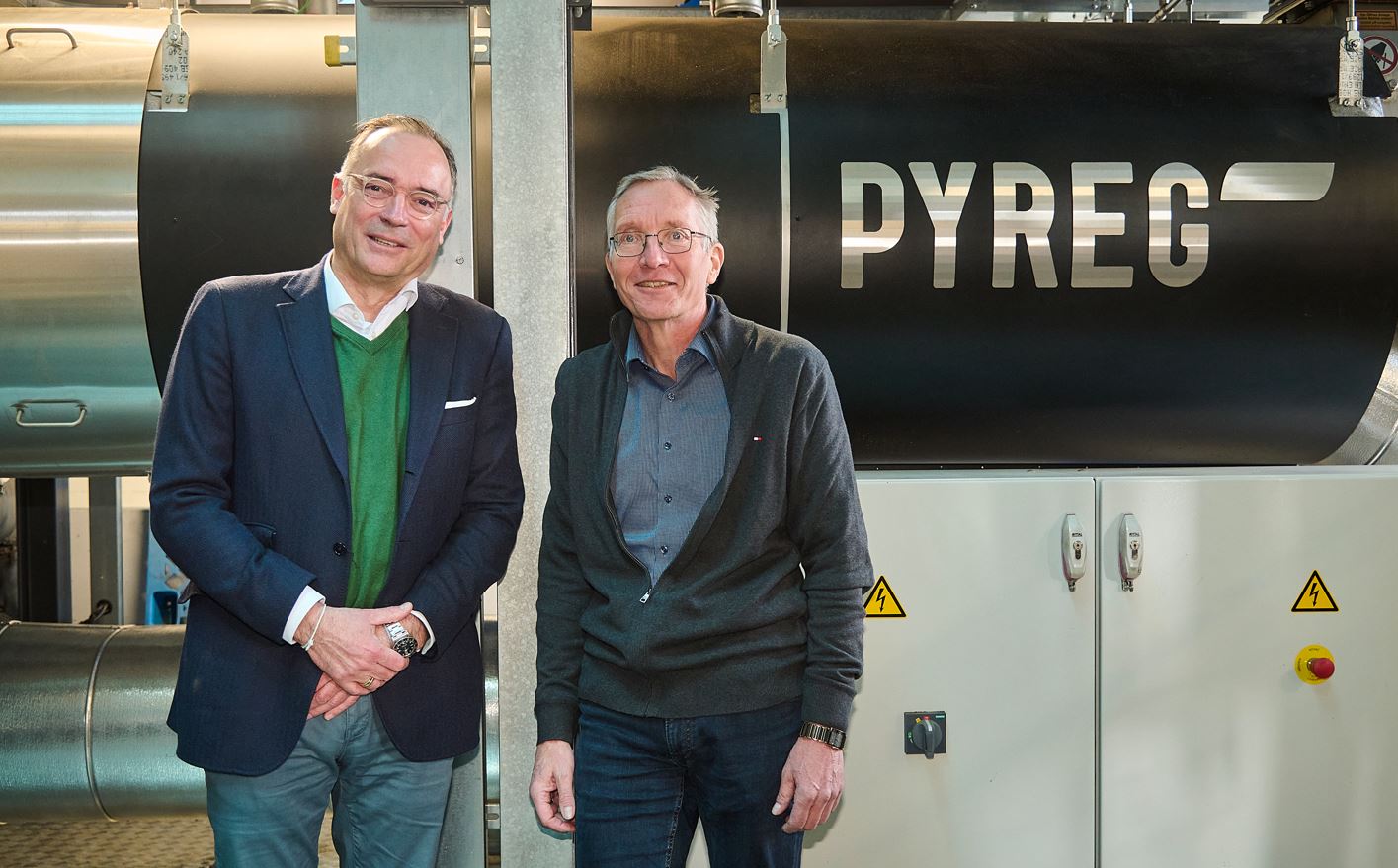

thyssenkrupp rothe erde is breaking new ground in climate protection: with a carbonization plant that is unique in this form in Germany to date, the company is taking a major step toward reducing CO2 with PYREG’s innovative NetZero technology.

In the carbonization plant, residual wood is carbonized in a pyrolysis process. This produces regenerative heat and biochar. „Our carbonization plant is unique in Germany in terms of its dimensions and is the first time negative emission technology has been integrated in a German industrial group,“ explains Dr. Wilfried Spintig, COO at thyssenkrupp rothe erde. „We use the heat generated in the pyrolysis process for our production site in Lippstadt and can thus cover around 40% of our on-site heat requirements.“ This renewable heat replaces previously fossil fuels. By way of comparison, the heat produced in the plant is equivalent to the annual demand of almost 300 households.

The feedstock used in Lippstadt is unprocessed and uncontaminated wood, consisting on the one hand of packaging residues and on the other of suitably dried green waste. Around 2,500 metric tons of residual wood are used annually to generate over 5,300 MWh of heat and around 640 metric tons of biochar, which is used among other things as a soil conditioner in agriculture. „thyssenkrupp rothe erde will be climate-neutral by 2050, and to achieve this we are also constantly looking for new ways to implement decarbonization at our company,“ explains Wilfried Spintig. „This plant is also a pilot project for us and, in our eyes, can be a building block for a meaningful jump-start on the way to decarbonization for other industries as well.“

foto / source: Christian Deutscher, thyssenkrupp rothe erde

0 Kommentare