The industry leading CO₂ removal technology (CDR)

Proven:

Worldwide, we have already installed over 50 plants for our customers since 2009. These PYREG systems remove more than 30,000 metric tons of CO₂ annually and, with 75 GWh, cover the annual heating requirements of around 5,000 households. Our technology is considered a reference by the U.S. Environmental Protection Agency and is EBC type-certified (European Biochar Certificate).

Sustainable:

PYREG carbonizations systems provide a circular economy solution – closing the loop by recycling residual materials into high-quality biochar and renewable energy. If the biochar is added to a permanent carbon sink, e.g. in agriculture, viticulture or building materials, the recycler can also generate Carbon Credits.

Scalable:

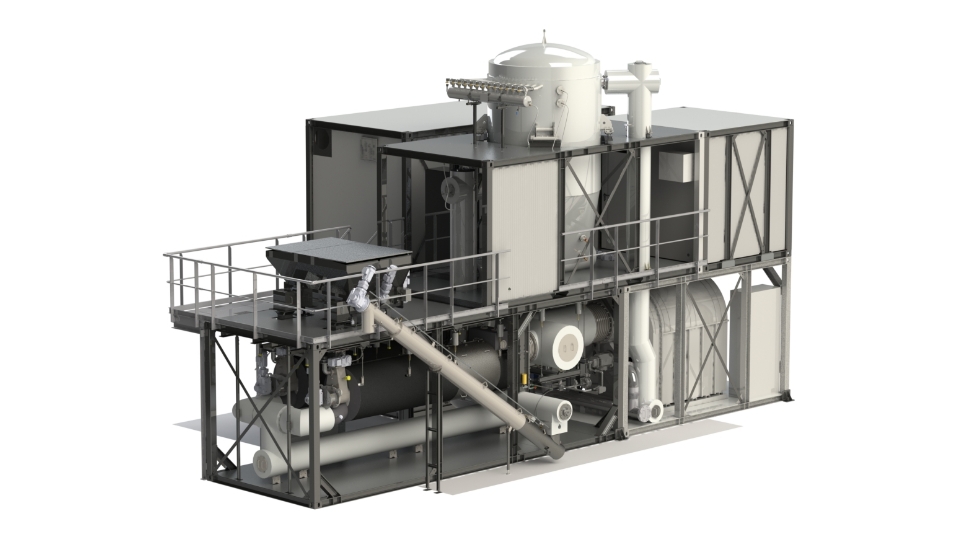

PYREG carbonization systems are rated at the highest Technology Readiness Level (TRL) 9. These systems feature a modular design, enabling us to deliver and install them, with minimal site requirements, in just a view days. Our systems can function as stand-alone units, or be combined as a multi-unit installation.

Decentralized:

The modular design allows us to set up PYREG systems at the source of the waste stream – close to production and decentralized. This is how you can transform your production site, which is producing organic residues, into a Net-Zero-site, which is producing value – no transport costs and prevention of additional, transport-related CO₂-emissions.

In total, our 50 carbonization systems are generating:

Biochar

≈ 8.800 t

CO₂-Sequestration

≈ 30.000 t

Phosphate Recycling

≈ 2.400 t

PER YEAR

50+

PYREG systems worldwide

approx.

5 Mio.

trees replaced

75 GWh

renewable energy/year

Award winning technology for climate protection

As the developer and pioneer of this carbonization technology, we are not only the world market leader, but have also received several awards, including: Finalist of the New Energy Challenge 2022, winner of the Watt d’Or 2022, Nominee of the German Sustainability Award 2022 and many more.

One technolgy – many solutions

valuable Biochar

Carbonize your residual materials into Biochar! This enables the permanent storage of CO₂. Biochar can be used as a valuable soil conditioner, feed additive or as a component in building materials, such as concrete and asphalt.

Closing material cycles

PYREG systems provide a multi material capable solution – transforming your WASTE (woody residues, rubber, plastics, packaging, composites, food waste, sewage sludge, manure, digestates, etc.) into VALUE. PYREG enables you to close your material cycle, decarbonize and drive a circular economy.

Renewable energy from your own resources

PYREG carbonization systems deliver clean, renewable thermal energy – as either hot water/oil, steam or electricity (via ORC). This thermal energy can be used, for example, in district heating applications, supplying up to 400 households per year.

CO₂-Removal and Carbon Credits

The controlled carbonization of the biogenic residues prevents a large part of the carbon contained in the biomass from escaping into the atmosphere. A PYREG plant thereby binds up to 3 t CO₂ per t biochar (with approx. 80% C-content, process-related deductions according to EBC sink not yet considered). If this biochar and the CO₂ bound in it is put into a permanent carbon sink as a soil improver or filler, the recycler receives carbon credits.

How to remove CO₂ from the atmosphere

Interested in the most efficient carbonization systems in the world?

#Turnpositivenow Blog

Welcome to PYREG, Alexander!

PYREG is excited to announce the addition of Alexander Friedrichkeit as Chief Sales Officer. With extensive experience and a proven track record in the energy sector, Alexander will bring valuable leadership and business development skills to to the PYREG team.

Welcome to PYREG, Alexander!

PYREG is excited to announce the addition of Alexander Friedrichkeit as Chief Sales Officer. With extensive experience and a proven track record in the energy sector, Alexander will bring valuable...

Looking for even more information? Take a look at our blog as well.